You have come to interview a man about his replicating machine. You hope it might make a good article for a magazine. You park your car and observe your surroundings.

The University of Bath sits on top of a hill, high above the city. It is a grubby collection of gloomy architectural horrors, all gathered in one place for mutual support. Thank God they built it up here on the hill, you think, far away from all the tourist attractions. The wind roars between the buildings and slices across the car park, greeting visitors with an ice-cold slap in the face. You shiver.

Within the university is a department, a department of mechanical engineering. The department is very much like other academic departments: dimly lit, easy to get lost in, notice boards on almost every available patch of wall. The corridors are long and punctuated by double doors. The lighting is functional. The flooring is buffed every night by a team of cleaners, long after the last students have decamped to the Union Bar. Inside one of its offices sits Dr. Adrian Bowyer.

Adrian Bowyer is very much like other academics. He has a slightly amused air about him; he potters from place to place in an endearing manner. As soon as he opens his mouth, you know that he is many, many times more intelligent than you are. You consider the questions you’d prepared for this interview, and wonder if perhaps they aren’t good enough. Too late to prepare further, though. Adrian Bowyer is leading you out from his office, down to the laboratory. He’s taking you to see his replicator.

One set of double doors. Another. Now you’re in a more modern part of the building, and you go through a security door. Adrian Bowyer taps a code number into a keypad to make it open. Beyond, you emerge on a gallery, a much larger room that extends downwards and outwards, out of sight. There’s machinery down there. Robots.

The replicator is an approximate cube of metal rods, plastic widgets, and the wooden shelf. To be frank, it doesn’t look terribly exciting.

Adrian Bowyer strides on, though, and the robots are left behind. You have more interesting things to see.

The lab with the replicator is much like any other lab. In fact, less exciting at first, because there are no obvious signs of robots. You look around. You see Lego bricks on a shelf. Adrian Bowyer directs you to the back of the room, by the window.

And there it sits, the machine you came to see. It has recently replicated a part of itself, leaving behind a plastic widget on a wooden shelf, and a small trail of white goo, like a plastic snail’s footprint. The replicator itself reminds you of Orac, the smarter-than-thou portable computer they carried from place to place in Blake’s 7. You loved that show when you were a kid. The very last episode of the very last season clashed with your opportunity to go and see Star Wars at the cinema. You picked Star Wars. This replicator brings those memories back, layer by layer, replicating themselves in your mind.

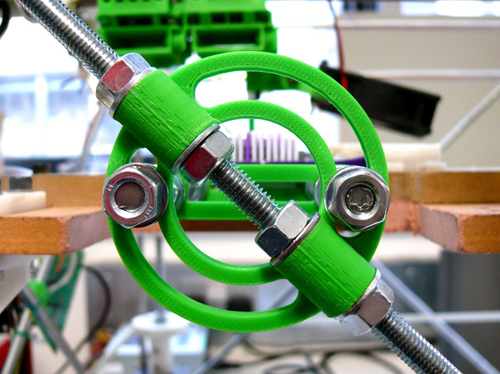

The replicator is an approximate cube of metal rods, plastic widgets, and the wooden shelf. It is connected to an old computer. To be frank, it doesn’t look terribly exciting.

But Adrian Bowyer is incredibly excited by it. This machine, he says, is at a pivotal point in its history. It’s called RepRap. And, by the way, it’s not a replicator.

Well, it sort of is, you suggest hopefully, because you’d been planning to use that word as the hook for your article.

No, says Adrian Bowyer, it’s not. It’s a replicating rapid-prototyper. As it happens, yes, it is capable of replicating itself. But it’s really a rapid prototyper. Like a printer: You tell it what shape to make, and it will make it. It looks a bit useless and weird, this collection of bits, but Adrian Bowyer has dedicated years of his life to it. And it has reached something of a milestone: it can fabricate all the parts needed to make a copy of itself. So in a manner of speaking, it self-replicates.

You beam inwardly. There you are. Replicator. See?

Right now, if you had about $500 or $600 to spare (that’s £300-ish to your mum and your friends), you could put one together yourself. In your kitchen, or your garden shed, or your basement laboratory if you had one. You won’t, of course, because you can think of much better things to spend your money on, but Adrian Bowyer thinks that some people will. And because each RepRap can fabricate the parts to make another RepRap, the theory goes that sooner or later, a certain critical mass will be reached, and RepRaps will start repping themselves everywhere.

That mass has not been reached yet. But Adrian Bowyer told you on the phone before you came to see him that it’s not far away. He wants to do to the manufacturing industry what the MP3 file did to the music business. He wants to see a repped RepRap in every home, making… things. Things for people to use. He wants RepRaps themselves to grow, to thrive, to rep and morph and fab themselves into new ideas, new machines—all of them making stuff for people. Stuff that today, we get manufactured in a distant country, shipped across the globe in a metal crate, and sold to us in soulless malls. Adrian Bowyer wants an end to all that. A new way of life.

He sees a sci-fi future for us, one in which goods are manufactured in a kitchen cupboard while you sleep.

He means it. And he’s not a breathless fanatic, not a wide-eyed hippie, not some random sycophant looking for citation fame. He’s a very mild, softly spoken academic with an office in a typical corridor in a typical department in a windswept university that sits on a hill. That’s who Adrian Bowyer is. He sees a sci-fi future for us, one in which goods are manufactured in a kitchen cupboard while you sleep, one in which your RepRap is connected to the web and has a menu of items for you to make—something a bit like the iTunes Music Store, perhaps. You tap an icon for the thing you want, then wait for it to appear. When he says these things, they sound incredibly plausible. Enticingly real.

It’s not the sci-fi future yet, though. The point that has been reached, the point we’re at now, is the early ’80s, he says.

You are confused. The early ’80s?

It was in the early ’80s that the first personal computers appeared, he explains, but not as finished products that we buy today. They were in kit form. People purchased the kit because they were interested enough to spend time turning it into a functional computer. That’s where RepRap is, says Adrian Bowyer. People who are interested enough can start now, building machines themselves, sourcing the materials and parts any way they like.

But give it 20 years, says Adrian Bowyer. Give it 20 years to mature the way personal computers have matured. Where will it be then? What are the possibilities?

A wide-eyed hippie would go all misty-eyed and Messianic at this point, but Adrian Bowyer just blinks and smiles. Then he turns and leads you back through the lab, back towards his office where you will end the interview, thank him for his time, and ponder which magazine to pitch your story to first. On the way out you pass the Lego bricks you saw on a shelf earlier, and mention it out loud. Adrian Bowyer responds mildly, speaking over his shoulder—Lego’s fabulous stuff, he says. They manufacture it to very tight specifications. That’s what makes it stick together so beautifully.